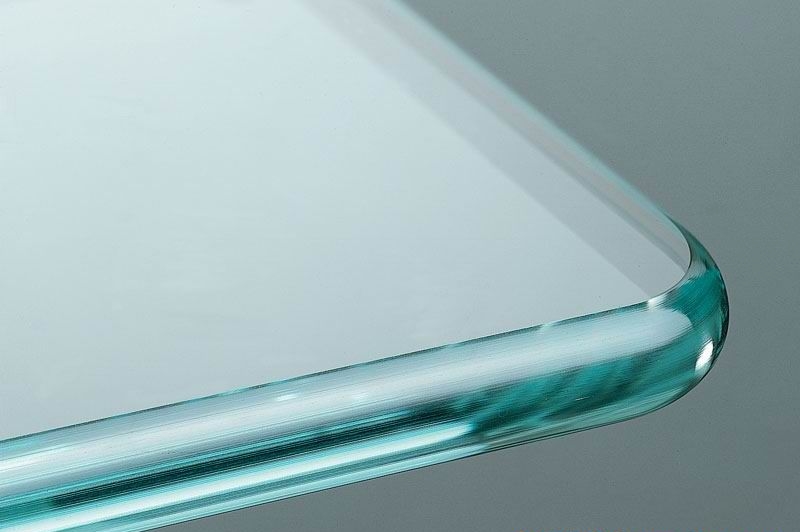

Tempered /toughened glass is a type of safety glass processed by controlled thermal or chemical treatments to increase its strength compared with normal glass. Tempering puts the outer surfaces into compression and the inner surfaces into tension. Such stresses cause the glass, when broken, to crumble into small granular chunks instead of splintering into jagged shards as plate glass (a.k.a. annealed glass) does. The granular chunks are less likely to cause injury.

Properties

Tempered/Toughened glass is physically and thermally stronger than regular glass. The greater contraction of the inner layer during manufacturing induces compressive stresses in the surface of the glass balanced by tensile stresses in the body of the glass.The smaller glass particles will be then broken.

Any cutting or grinding must be done prior to tempering. Cutting, grinding, and sharp impacts after tempering will cause the glass to fracture.

| Products specification: | Flat tempered glass |

| Maximum dimension: 3000mm x 2000mm | |

| Minimum dimension: 300*300mm | |

| The thickness of glass: 4-25mm | |

| Products application: | Door, window, curtain wall, ceiling, floor, partition wall, roof lighting, show window of the shop and roof window of factory building. There is extensive application in vehicle, steamer, bank, jeweler's shop, villa, etc. |